Corrosion Data - Right on time

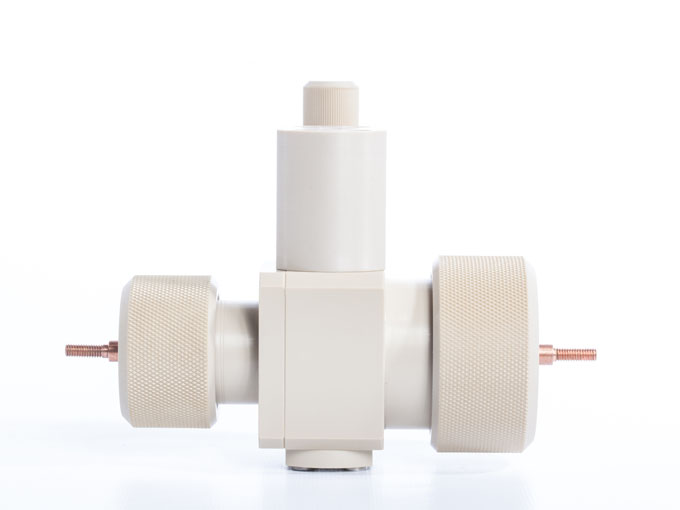

The Automated Corrosion Test System is high-throughput flow equipment consisting of independently controlled test cells. A system can comprise of many cells chained together allowing simultaneous testing of samples. User-friendly software is integral to the system allowing easy collection of corrosion data.

At the click of a button our Zebrafish can control the environment of the sample. With electrochemical instrumentation from Intertek (our preferred partner), users can perform experiments such as polarisation resistance, voltammetry and constant potential experiments incorporating user-defined conditions of electrolyte flow and temperature.

The electrolyte can be sampled for metal ion content and tests can be carried out using a multiplicity of additives to evaluate accelerated degradation.

In addition to yielding high quality corrosion data a great deal faster than conventional test methods, the high throughput approach enables the evaluation of a more complete range of parameter variables than was previously possible.

- Flow cells for electrochemistry

- Performs multiple tests simultaneously

- Precise temperature control

- Modular construction

- Small volume, resource efficient design

- Easy to use and set up hardware – plates/tokens can be changed in seconds

- User friendly software for easy data collection and manipulation

- Integrates seamlessly with Intertek instrumentation for standard tests e.g. polarization resistance and voltammetry

Next

Advanced Temperature Management

Our Zebrafish reduces process variability while increasing process reproducibility. Each station operates independently, either under manual or computer control.

The Zebrafish has been designed to deliver accurate temperature profiles under a range of flow conditions - you can achieve a controlled environment for observation, manipulation and testing samples.

Features of the Zebrafish include

- Exchangeable electrochemical cells

- Programmable temperature capability, from ambient to +80 C

- Simple operation

- Energy efficient, very low running costs

- A range of electrochemical cells

- Adaptable to many applications

- Compact footprint

- Delivers corrosion data quickly and safely

A Three in One Electrode Cell may be used when the electrolyte contains additives that may affect the performance of the reference electrode. In these cases, we offer housing the electrodes in an epoxy resin. Our method leads to a mould containing all three electrodes - WE, CE and RE. The epoxy mould is compatible with our cell so the construction is easy to assemble. Cambridge Reactor Design offers the tools necessary for this application. For more information, refer to the technical document "Three in One Electrode Cell in the Specification Section.

Other cell designs may be made on request.

Next

Corrosion testing made easier

The platform can be individually set to give the optimum conditions for examining the impact of the electrochemistry on a test sample.

The Zebrafish is a walk up system that was developed by corrosion chemists for safe robust and repeatable processing. It is simple to use and eliminates the need for large volumes of electrolyte and bulky glassware. Token samples take seconds to change. The high quality design of our Zebrafish is an improvement to your working environment.

Conventional three electrode cell (Glass construction) -

Constant Temperature Data

Conventional three electrode cell (Glass construction) -

Temperature Ramp

Conventional three electrode cell (PEEK construction) -

Constant Temperature Data

Conventional three electrode cell (PEEK construction) -

Temperature Ramp

Next